BLH Conveyor & Machine Guarding Solutions™ have been developed to combat the inadequate safe guarding of machinery in an increasingly mechanised world.

BLH Conveyor & Guarding Solutions™ are designed to minimise the risk of injury from:

- Conveyors

- Moving machinery

- Plant and equipment

BLH Guarding Solutions™ are based on moulded modular polymer components that are easy to install and allow simple innovative clip and snap on installation.

BLH Guarding Solutions™ are based on the same components plus more as used in our BLH Stop Drop™ Barricading. Additional features have been added due to the wide variety of rotating and moving machinery that require guarding with doors and hinges for entry points and inspection points as required.

One of the major advantages our guarding solutions have over current guarding methods is the suitability of our products for use in highly corrosive areas where steel is sometimes not an option. The Offshore Oil and Gas Industry is a perfect example where salt corrosion of traditional guarding materials is an issue, as are remote mine sites with corrosive fluids used in processing operations.

BLH Guarding Solutions™ offer a universal solution to prevent injuries, incidents and costs arising from equipment that requires guarding.

Further unique and innovative features that our system incorporates in the design include:

- Adaptable as guarding on conveyors, actuators, rotating machinery and many more applications

- Recyclable for a safer environment

- Engineered to relevant guarding standards

- Anti Static (on request)

- Anti Corrosive

- Fire Resistant

- Impact Resistant

- Chemical Resistant

- UV Stabilised

- Available in a range of colours [standard colour Australian Standard Y14]

- Anti Ageing

- Non Conductive

- Light weight

- Wind Rated – wind tunnel tested

- 300 kilometre per hour wind loading

- No sharp edges

- No pinch points or catch points

- Reusable

- Suits permanent or temporary installations

- Easy to remove and store

- Our guarding systems will accommodate a variety of sizes and configurations of equipment

- Low cost installations

- Hot work permits not required

- Fast and easy to install minimising disruptions onsite

- Glare resistant

- Non heat conductive

View Information regarding standards and compliances about our BLH Conveyor and Guarding Solutions™ product.

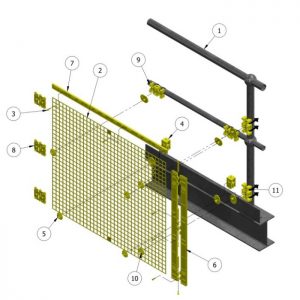

| ITEM NO. | DWG/PART NUMBER | DESCRIPTION | QTY. |

|---|---|---|---|

| 1 | NOT PART OF SUPPLY SCOPE | PLATFORM STRUCTURAL COMPONENTS TO AS1657 | 1 |

| 2 | BLH-SDB-002-008 | STOP DROP MESH PANEL | 1 |

| 3 | BLH-SDB-002-029-M2 | SECURING BARBING PIN | 7 |

| 4 | BLH-SDB-001-005-M2 | KICK RAIL CLIP ASSEMBLY | 2 |

| 5 | BLH-SDB-002-006-M2 | MESH CLIP BUTTON | 2 |

| 6 | BLH-SDB-001-006-M2 | MESH PANEL VERTICAL JOINER ASSEMBLY | 1 |

| 7 | BLH-SDB-002-019-M2 | MESH PANEL TOP CAPPING RAIL | 1 |

| 8 | BLH-SDB-001-011-M2 | ADJUSTABLE JOINER ASSEMBLY (OPTIONAL ITEM REPLACES ITEM 8) |

3 |

| 9 | BLH-SDB-001-012-M2 | ADJUSTABLE MOUNTING BLOCK ASSEMBLY | 2 |

| 10 | BLH-SDB-002-006-M2 | MESH CLIP BUTTON | 4 |

| 11 | BLH-SDB-001-012-M2 | ADJUSTABLE MOUNTING BLOCK ASSEMBLY | 2 |

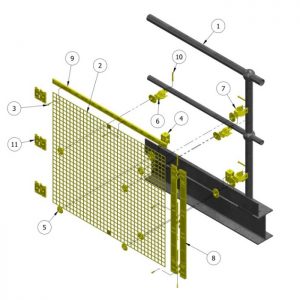

| ITEM NO. | DWG/PART NUMBER | DESCRIPTION | QTY. |

|---|---|---|---|

| 1 | NOT PART OF SUPPLY SCOPE | PLATFORM STRUCTURAL COMPONENTS TO AS1657 | 1 |

| 2 | BLH-SDB-002-008 | STOP DROP MESH PANEL | 1 |

| 3 | BLH-SDB-002-029-M2 | SECURING BARBING PIN | 7 |

| 4 | BLH-SDB-001-005-M2 | KICK RAIL CLIP ASSEMBLY | 2 |

| 5 | BLH-SDB-002-006-M2 | MESH CLIP BUTTON | 6 |

| 6 | BLH-SDB-001-003-M2 | MIDDLE RAIL CLIP ASSEMBLY | 2 |

| 7 | BLH-SDB-001-004-M2 | STANCHION CLIP ASSEMBLY | 2 |

| 8 | BLH-SDB-001-006-M2 | MESH PANEL VERTICAL JOINER ASSEMBLY | 1 |

| 9 | BLH-SDB-002-019-M2 | MESH PANEL TOP CAPPING RAIL | 1 |

| 10 | BLH-SDB-002-011-M2 | CLIP TAMPER PROOFING PIN | 4 |

| 11 | BLH-SDB-001-011-M2 | ADJUSTABLE JOINER ASSEMBLY (OPTIONAL ITEM REPLACES ITEM 8) |

3 |